The Versatile World of Cleanrooms: Beyond the Stereotype

Cleanrooms are often visualized as pristine, white spaces where scientists in lab coats conduct research. While this image holds true, the application of cleanrooms extends far beyond the confines of research and development. As an expert in modular building enclosures and cleanrooms, I’ve witnessed firsthand the transformative impact these controlled environments have across a myriad of industries. This blog post aims to shed light on the diverse applications of cleanrooms, illustrating their critical role in not just safeguarding products and processes but also in fostering innovation and ensuring safety.

The Quintessence of Cleanrooms

At their core, cleanrooms are designed to maintain extremely low levels of particulates, such as dust, airborne microbes, aerosol particles, and chemical vapors. Precision control over environmental parameters, including temperature, humidity, and pressure, is also a hallmark of these specialized spaces. This meticulous control is achieved through sophisticated filtration systems, stringent protocols, and advanced materials and technologies.

The Spectrum of Cleanroom Applications

- Pharmaceuticals and Biotechnology

- In the realm of pharmaceuticals and biotechnology, cleanrooms are indispensable. They ensure the sterility and purity of pharmaceutical products, from injectables to oral medications, thereby safeguarding patient health. Biotechnological applications, particularly those involving genetic manipulation and cell culture, necessitate cleanrooms to prevent contamination and ensure the integrity of experimental results.

- Semiconductor and Electronics Manufacturing

- The semiconductor and electronics industries are perhaps the most recognized beneficiaries of cleanroom technology. The fabrication of microchips and electronic components demands an environment free from particulates that could impair the functionality of these microscopic circuits. Cleanrooms facilitate the production of high-quality, reliable electronic devices, from smartphones to advanced computing systems.

- Aerospace and Defense

- In aerospace and defense, cleanrooms play a pivotal role in the assembly and testing of spacecraft, satellites, and sensitive defense equipment. The precision required in these applications cannot tolerate any form of contamination, making cleanrooms essential for the development and maintenance of critical technology.

- Medical Devices and Implants

- The manufacturing and packaging of medical devices and implants are conducted in cleanrooms to ensure sterility and compliance with stringent regulatory standards. This is crucial for devices that come into direct contact with the human body, such as surgical instruments, implants, and prosthetics.

- Food Industry

- While not as commonly associated with cleanrooms, the food industry increasingly employs these controlled environments to enhance food safety and extend shelf life. High-risk products, such as baby food and dairy products, benefit from the contaminant-free processing that cleanrooms provide.

- Nanotechnology

- At the forefront of technological advancement, nanotechnology relies on cleanrooms to manipulate matter at the molecular and atomic level. The precision required in this field is unparalleled, with even the smallest contaminant capable of derailing experiments and production.

- Optics and Photonics

- The fabrication of optical components, such as lenses, mirrors, and fiber optics, requires the precision that only cleanrooms can offer. These components are integral to a wide range of products, from cameras to advanced scientific instruments.

The Evolution of Cleanroom Design and Technology

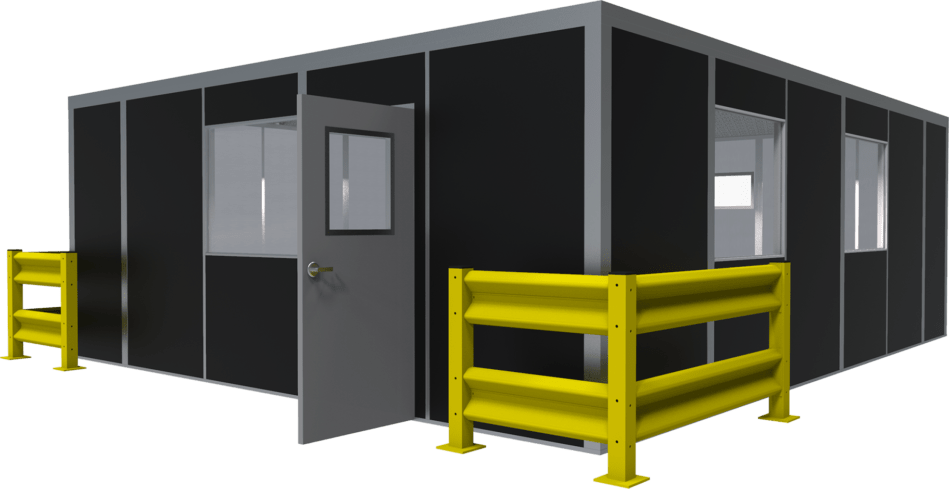

The expanding application of cleanrooms across various industries has spurred innovation in cleanroom design and technology. Modular cleanrooms, in particular, have gained popularity for their flexibility, scalability, and cost-effectiveness. These prefabricated units can be customized to meet the specific requirements of different industries, ensuring optimal conditions for each unique process.

Moreover, advancements in materials, filtration systems, and monitoring technologies have enhanced the efficiency and effectiveness of cleanrooms. These innovations not only improve the quality of products and processes but also contribute to energy conservation and sustainability.

Conclusion

Cleanrooms are the unsung heroes of numerous industries, playing a crucial role in ensuring the quality, safety, and reliability of a wide array of products and processes. From healthcare to high-tech electronics, the applications of cleanrooms are as diverse as they are critical. As we continue to push the boundaries of science and technology, the importance of cleanrooms in facilitating innovation and maintaining standards cannot be overstated. In the ever-evolving landscape of cleanrooms, one thing remains constant: their indispensable role in driving progress across industries.