Most warehouses eventually reach a stage where the ground space feels too full to function well. Inventory may get stacked higher and higher, lanes become smaller, and the entire setup seems like an accident waiting to happen.

Most automatically assume that the best way forward is to expand the building or move to a bigger warehouse, both of which are huge pains to deal with, and as a result, the issues persist longer than they should.

But there’s a much easier solution. Businesses can use warehouse mezzanines to tap into vertical space that is unused, and this space can turn into a working platform, an extra storage space, or even office space.

In this article, we’ll cover the costs of staying in a crowded warehouse, what mezzanines are and how they can benefit your operations, some of their applications, and more.

The Price of an Overcrowded Warehouse

A crowded warehouse is painful for everyone involved, workers and managers alike, and even the business itself can suffer. Items like boxes get in the way, work areas overlap (which really shouldn’t), and things like accidents happen far more easily. Not to mention the stress of managing, or working in, such a place. Here are some of the main “costs” or downsides of running a warehouse in a tight space.

Lost Time

When selecting a warehouse, a business may want it to be as tight as their operation allows so that they can save money. However, in many cases, more space was needed than originally planned for, which ends up hurting the company through a thousand and one inefficiencies.

For instance, in a crowded space, basic tasks take longer. Equipment such as forklifts may not be able to pass through narrow spaces. Or, items may need to be moved out of the way to reach other items, all because of a lack of planned inventory space.

Needless to say, time is money, and such a state of affairs is anything but efficient.

Safety Hazards

Furthermore, when spaces get crowded, exits are obstructed and tight corners are created that may cause injuries. In many warehouses, such issues can even violate OSHA rules or fire codes. Walkways and aisles have to stay clear; otherwise, workers are prone to accidents.

Negative Impressions

It should go without saying that a messy warehouse doesn’t inspire confidence. Neither from clients nor employees. The latter may feel especially frustrated working in an area that’s out of control, and it may end up affecting their work, and then your bottom line.

What Is a Warehouse Mezzanine?

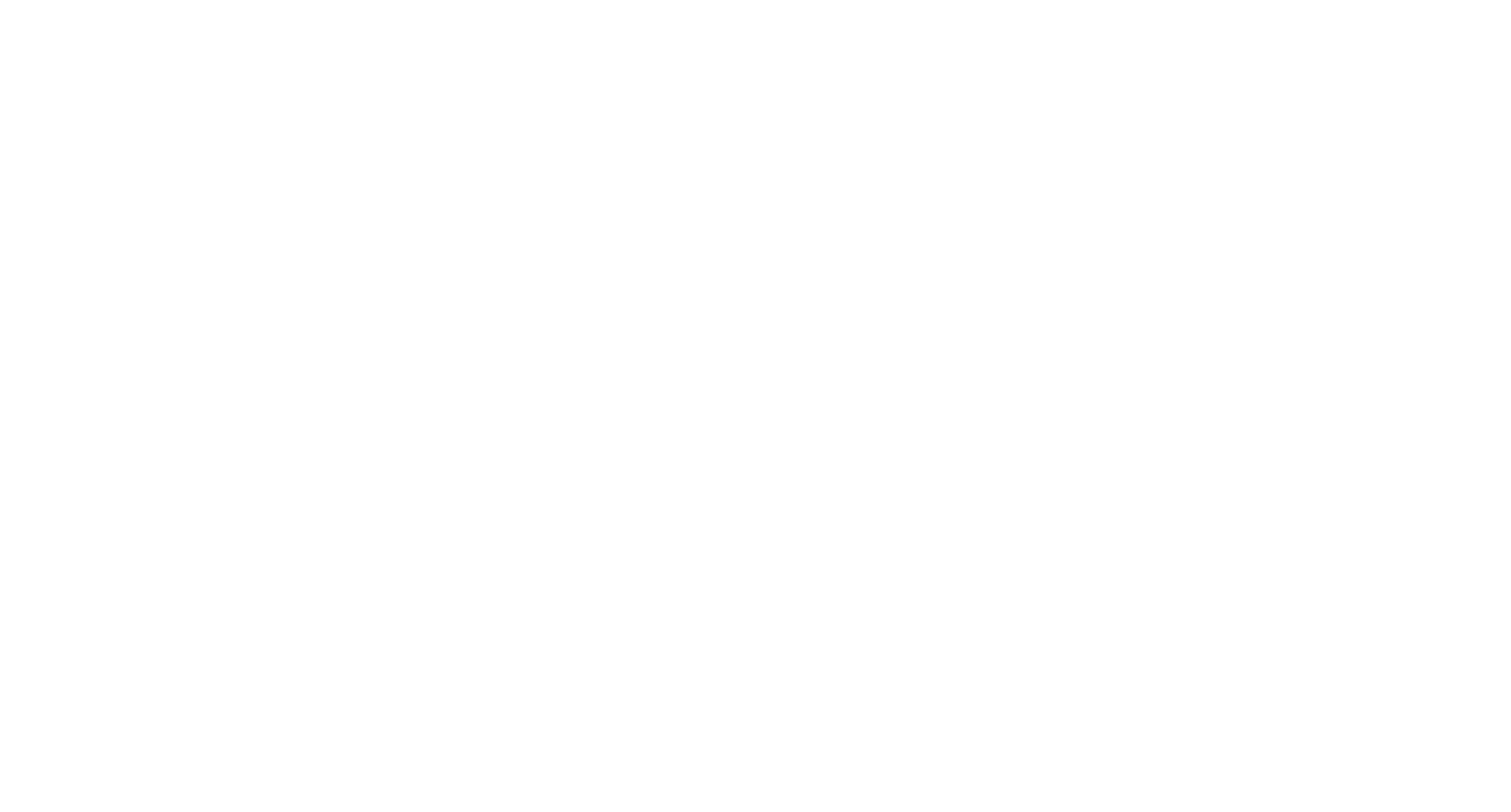

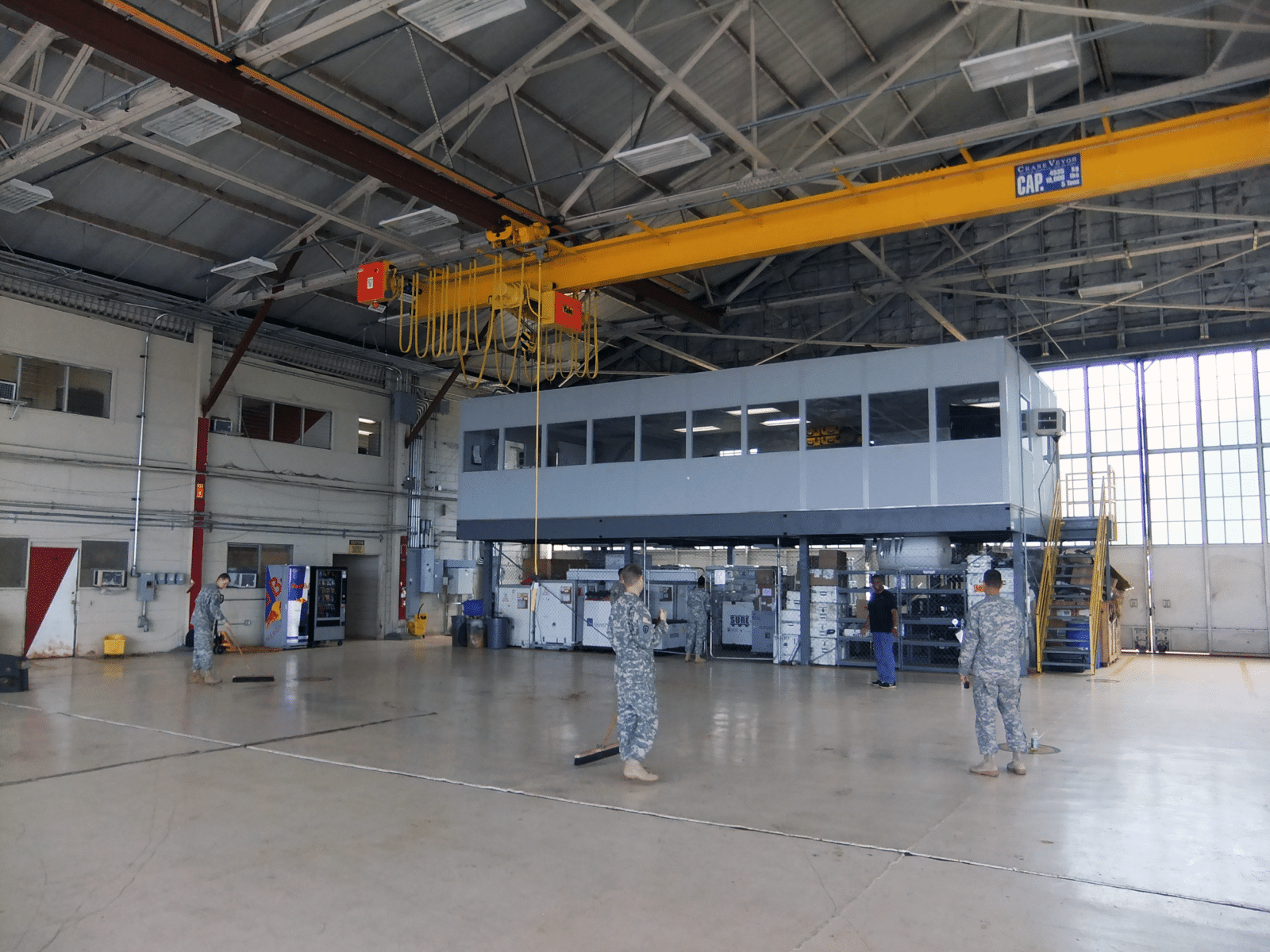

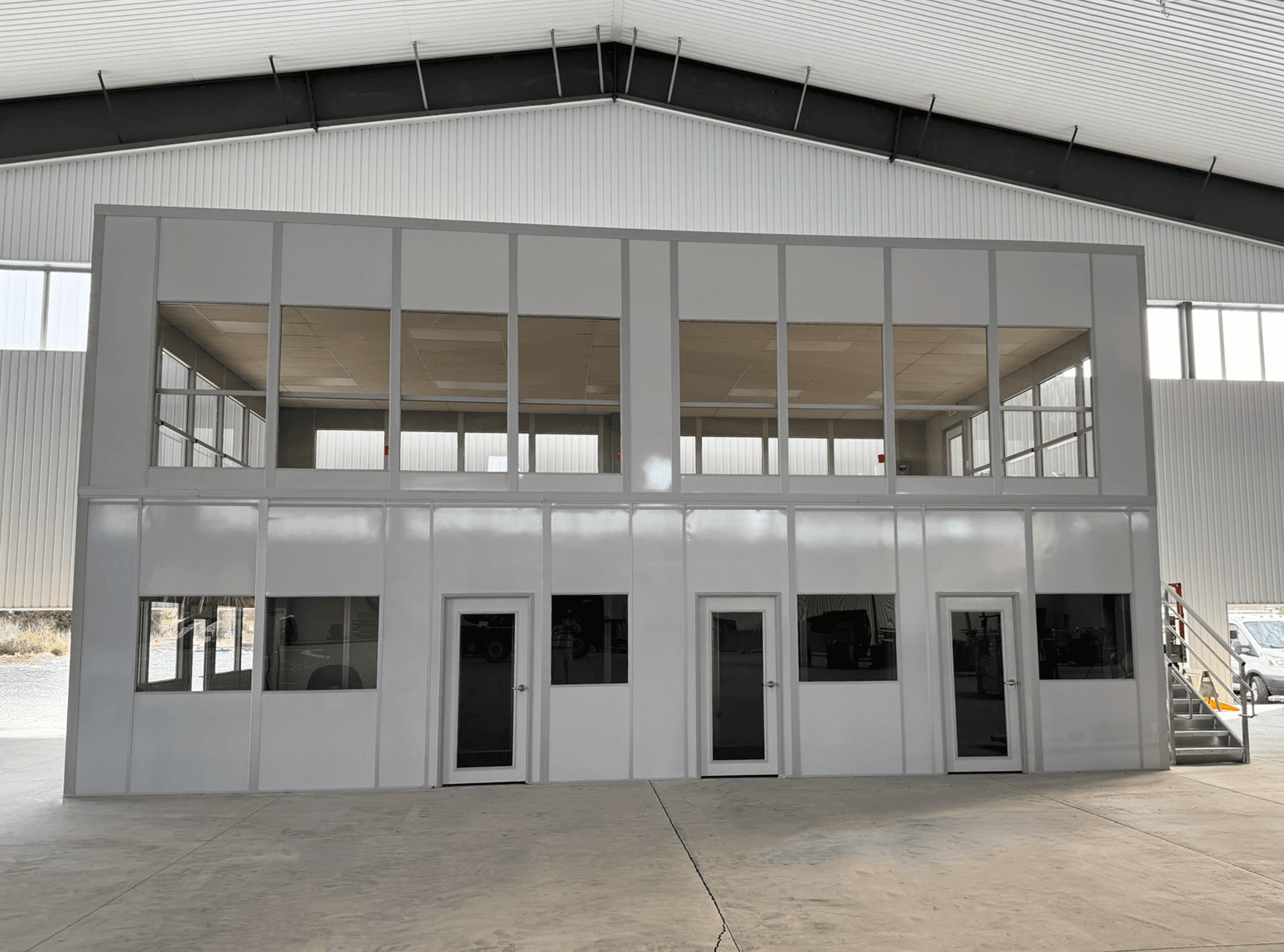

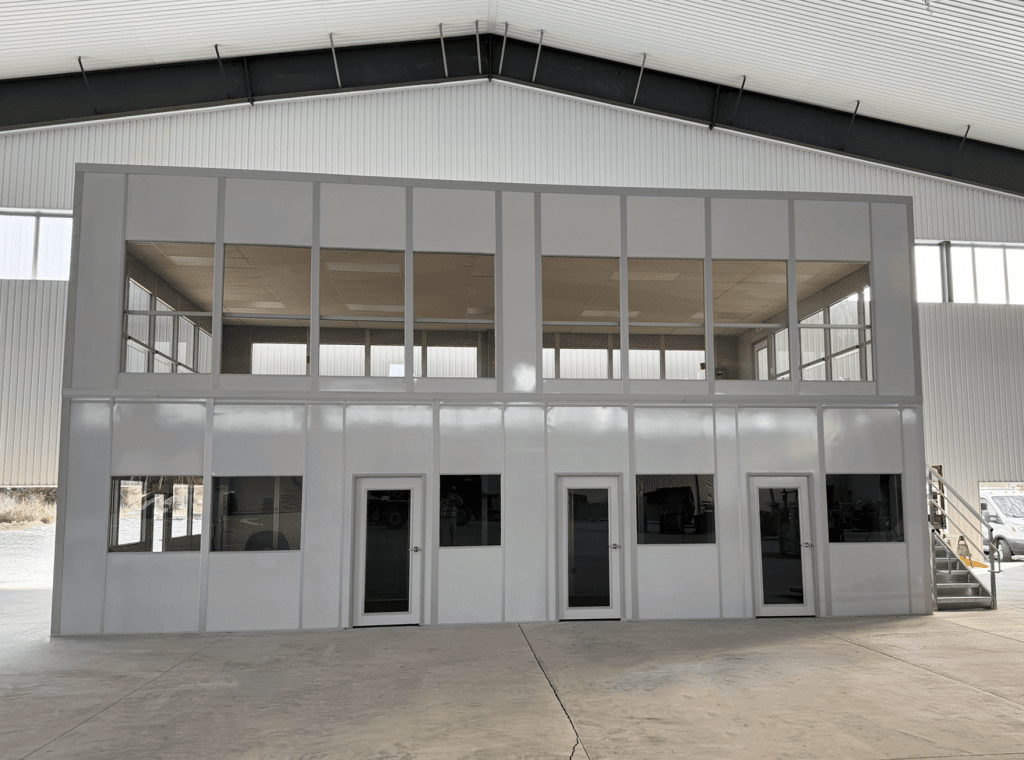

With all that being said, if you are stuck in a crowded warehouse, there is a relatively quick and easy solution. A warehouse mezzanine is a raised platform built within your existing space, which effectively creates a second floor that can hold inventory, heavy equipment, office space, or whatever you need it to.

It frees up ground space and makes use of vertical space instead, and it is far faster to install (while costing you less) than expanding your current building or moving to a new one.

Mezzanine systems are made from structural steel and when modular, typically bolt into place. What’s more, each can be custom-built to meet your specific warehouse needs.

Common Applications of Warehouse Mezzanine Systems

Warehouse mezzanines can be found in many different industries. However, here are a few of the most common applications for them:

- E-commerce fulfillment centers

- Manufacturing and production

- Logistics

- Retail

- Cold storage

- Food-grade facilities

Benefits of Installing a Warehouse Mezzanine Floor

Though we’ve covered the downsides of continuing operations in a crowded space, we haven’t discussed all the advantages of mezzanines themselves. Though the main problem they solve is reducing cluttered spaces, it’s not just about storage. Here are some of their main benefits.

More Storage Without More Square Feet

Mezzanines let you add more space. Or rather, they allow you to optimize on the space you already have. Instead of paying for a move or new real estate, you can unlock the area above the ground floor, while preserving it at the same time.

Better Organization

A mezzanine can also help separate your operations. Since it can be its own platform, built to carry heavy loads, you can store bulkier items on top of it, and the faster-moving ones below. Or, you could shift a ground-floor operation entirely to your mezzanine platform. Either way, they give you more flexibility in how you want to organize your space.

Low Costs

Compared to a renovation or a move, mezzanines are a serious bargain. They can also be installed much faster. This means there is less downtime at your warehouse (if any), and you can continue business as usual during installation.

The Bottom Line

Warehouse mezzanines can give you the space you need, and all without the costs and time loss of a move or expansion. They help you unlock vertical space, and therefore reduce clutter and create a more organized atmosphere for managers and employees alike.

FAQs About Warehouse Mezzanines

1. What flooring options are available for warehouse mezzanines?

A few common options include diamond plate, bar grating, Advantech, concrete, and more, depending on the application.

2. Are mezzanines compatible with conveyor systems or automation?

Yes, absolutely. Many warehouses use mezzanines to hold things like conveyors, sortation equipment, or automated storage. Platforms can be designed with openings, supports, and reinforcement.

3. How long do warehouse mezzanines typically last?

A steel mezzanine can last for decades with not much maintenance. Because they’re made from structural steel and designed to handle heavy loads, they continue to be reliable even with a lot of use.