Fiberglass reinforced plastic (FRP) panels have been widely used since the 1960s. They are known for their strength and light weight, and are used in the modular construction industry because of their low maintenance and other valuable features. In this article, we’ll define what FRP panels are, cover their benefits and applications, and compare FRP with other materials.

What are FRP Panels?

Fiberglass reinforced plastic panels are a mix of strong fiberglass and a special type of plastic, which makes the panels both sturdy and light weight. The fiberglass makes them strong, while the plastic creates a surface that is both smooth and non-porous. FRP panels as a whole are strong, light weight, and especially resistant to environmental factors, such as moisture and chemicals.

Benefits of FRP Panels

- High Strength Relative to Weight: As mentioned earlier, FRP panels are both strong and light weight. This, in turn, makes them ideal for modular structures, as they can be assembled and reassembled with ease.

- Corrosion Resistance: In any construction project, corrosion can become a problem. These panels, however, are able to handle weathering very well. They resist corrosion and chemical damage, which means they have a greater longevity than other materials.

- Low Maintenance: The smooth surface of these panels makes them easy to clean and maintain.

- Durability: Fiberglass reinforced panels are exceptionally tough. As a result, they do well in industrial applications, where materials need to withstand harsh conditions. They are also moisture resistant, preventing issues like mold and mildew.

- Safety Features: They can also be made to resist fire and chemicals, making them a smart choice in places where safety is important. The fire ratings of FRP panels help meet strict safety standards.

- Customization: These panels can be manufactured in a variety of textures and colors, which offers flexibility in design for modular offices, guard shacks, and more. Interested in customizing your space? Contact Allied Modular today to get a free quote and explore your options.

Applications of FRP Panels

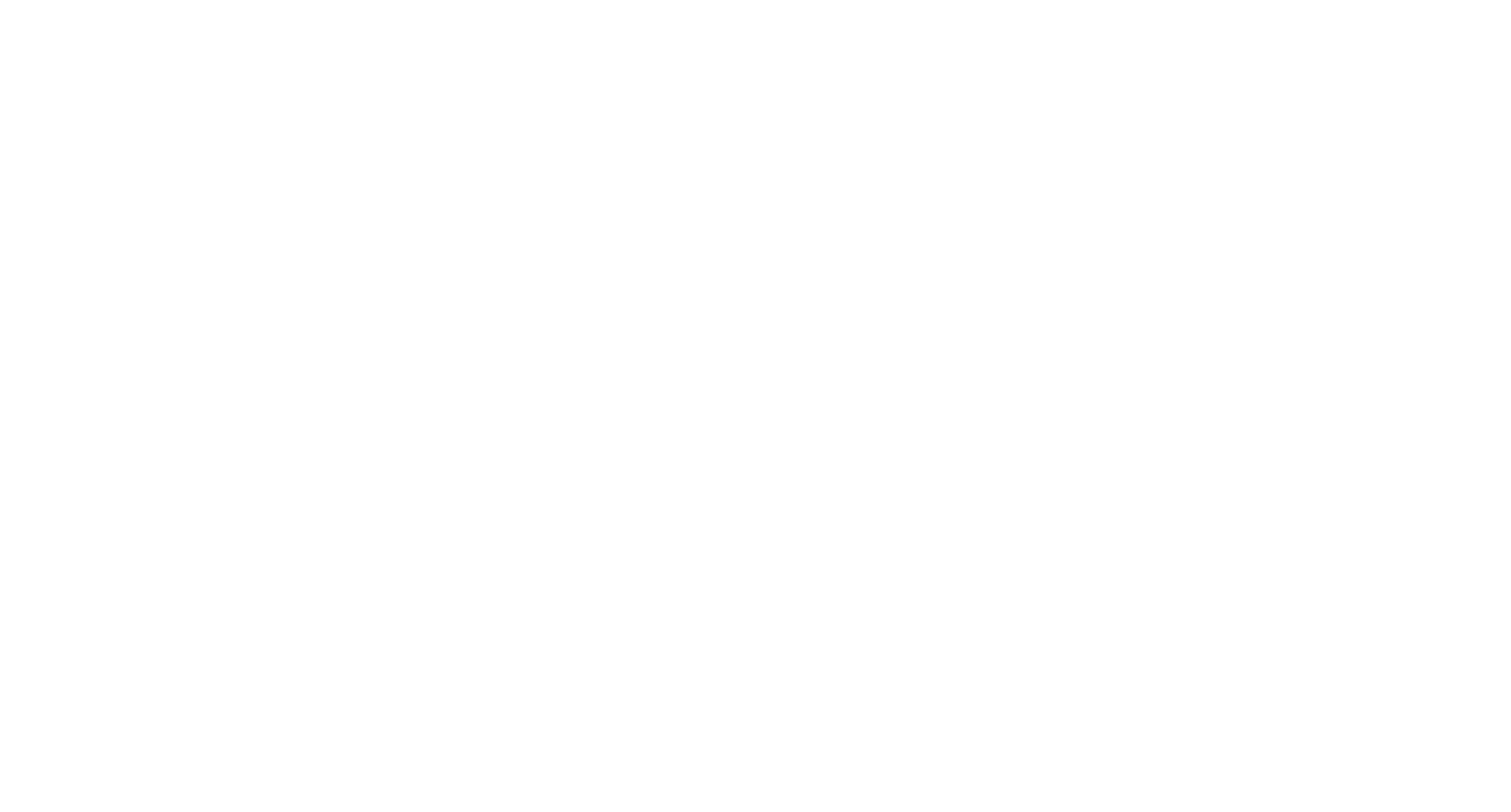

- Modular offices: These spaces rely heavily on FRP panels. At Allied Modular, we use these panels to create office spaces for a variety of business needs.

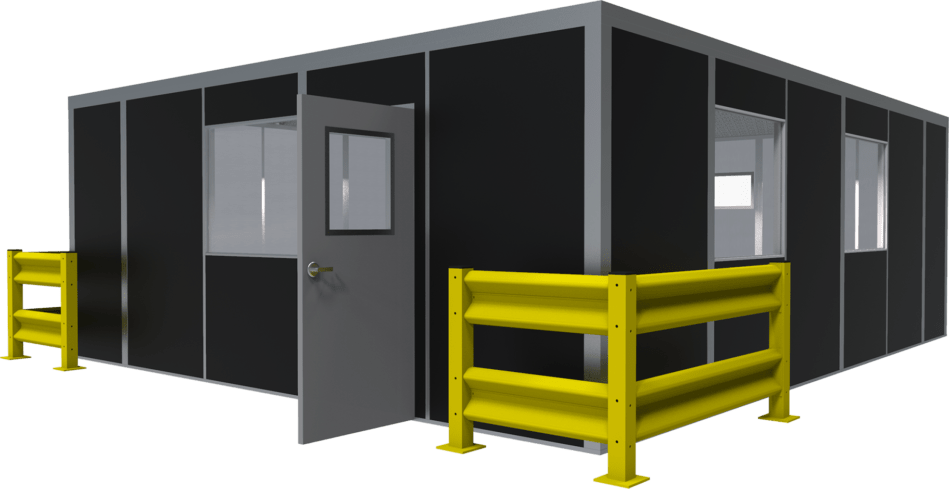

- Guard shacks: FRP panels provide lightweight and secure walls for guard shacks and security booths. Their strength and durability make them ideal for improving the safety of personnel.

- Machine enclosures: These panels can also be used for enclosing machinery in manufacturing environments. Because of their light weight, they are easy to install and quick to set up within warehouses or other manufacturing areas.

- Cleanrooms: FRP panels are especially useful in cleanrooms because of their non-porous surfaces. This makes cleaning simple, and prevents particles or germs from lingering in hard-to-reach places. They are widely used in the food processing industry due to their hygienic properties.

Comparing FRP Panels with Other Materials

FRP vs. Traditional Materials

- Steel and Aluminum: While steel and aluminum are strong, they are more liable to corrosion and are much heavier than FRP.

- Wood: Wood is less expensive, but it lacks the corrosion resistance of FRP.

Cost Comparison

- FRP panels may sometimes have a higher upfront cost than traditional materials. However, because of their low maintenance and longevity, they may be a more cost-effective choice.

The flame spread of FRP panels is also lower compared to some traditional materials, adding an extra layer of safety.

The Bottom Line

Fiber reinforced plastic panels are strong, durable, and can withstand various weather conditions, from rain and sun exposure to overall corrosion. They’re also tough against rough handling, which makes them preferable for many industrial uses. Further, they’re perfect for lots of different places, such as modular offices, guard shacks, machine enclosures, and cleanrooms. Choosing these panels means you’re getting a solution that’s not only built to last but also easy to take care of.

As a result, FRP panels are becoming increasingly popular in the United States. Many businesses are opting for these wall panels in their construction projects, appreciating the balance of strength, lightweight, and low maintenance. If you’re interested in learning more about our materials, check out our wall and ceiling product options today.