Sandwich panels are becoming a popular choice in modern modular construction. They are strong, insulated, and can be set up quickly, which makes them great them for countless applications. Whether they are for commercial buildings or industrial facilities, sandwich panels are a reliable and efficient way to create durable structures. In this article, we’ll go over what a sandwich panel is, along with its main parts, benefits, and applications.

What is a Sandwich Panel?

A sandwich panel typically consists of three parts: (1) an outer skin that provide strength and protection, (2) a core material with insulating or soundproofing qualities, and (3) an adhesive layer that sticks the outer skin to the core.

Outer Skin

The outer skin of sandwich panels is important both for structural integrity and environmental protection. They are the external layers that surround or encapsulate the core material, and in this way they make it durable. Some common materials for outer skin include:

- Fiberglass Reinforced Plastic (FRP): Great for moisture-prone areas. This material has excellent corrosion resistance and is both strong and lightweight.

- Prepainted Galvanized Steel: Excellent corrosion resistance and strength. It is able to withstand harsh weather conditions as well as UV radiation.

- Aluminum: Lightweight and corrosion resistant. Useful in a variety of climates and applications.

- Stainless Steel: Strong and easy to clean, making it a good choice for places that require strict hygiene, such as food processing plants or hospitals.

Core Materials

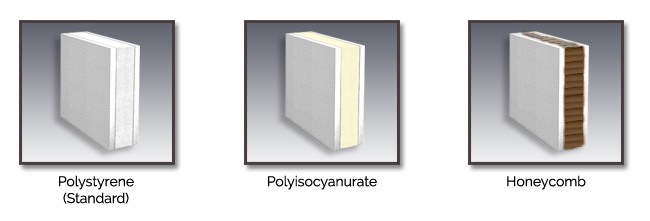

The core material is typically lightweight and may contain fire resistance and insulation properties. Some common core materials include:

- Polystyrene: Lightweight and provides good thermal insulation.

- Polyisocyanurate: Great for insulation properties and fire resistance.

- Honeycomb: High strength-to-weight ratio. Excellent for structural support.

Adhesive Layer

The adhesive layer is important because it binds the outer skin to the core material. It completes the panel and allows it to combine the properties of both the core and outer skin.

Wall Finishes

Wall finishes are materials applied to the surfaces of panels to improve their appearance or performance. Finishes can be used on both interior and exterior surfaces. Technically, wall finishes are not part of the structure of a sandwich panel, they are applied over them. A few common wall finishes include:

- Gypsum Vinyl: Smooth, strong, and easy to maintain, they are often used in modular building interiors.

- Composite: Made from a combination of materials, such as wood, plastic, and metal. Used for a variety of functions.

- Hardboard Vinyl: Combines the strength of hardboard with the customizability of vinyl coating.

- Plastics/FRP (Fiberglass Reinforced Plastic): Great for areas prone to moisture. It is corrosion resistant and low maintenance.

- Aluminum: Lightweight and rust resistant, often used to give interiors a modern look.

Benefits of Using Sandwich Panels in Modular Buildings

Sandwich panels provide a range of benefits that make them a superior choice for modular construction. Here are a few of the top advantages they provide:

- Strength: Sandwich panels are both strong and lightweight, which allows for long-lasting performance.

- Insulation: Core materials provide excellent insulation, which improves energy efficiency.

- Easy Installation: Their lightweight nature makes them easy to assemble and install; this, in turn, reduces construction time and labor costs.

- Customizable: Sandwich panels are available in a variety finishes and materials; they can be customized to fit in with existing styles.

- Low Cost: Compared to traditional construction materials, these panels are much more cost-efficient. They provide many of the same benefits while significantly reducing costs.

If you’re interested in learning more about how our sandwich panels can meet your construction needs, contact us today for a free quote.

Applications of Sandwich Panels

There are countless applications of sandwich panels, but here are a few that Allied Modular provides.

- Commercial Buildings: Modular offices, retail spaces, or guard shacks.

- Industrial Facilities: In-plant offices and other facilities.

- Temporary Structures: Exhibition halls, emergency shelters, and more.

The Bottom Line

Sandwich panels are becoming increasingly popular in modern construction due to their exceptional strength, superior insulation properties, and ease of installation. Whether for commercial or industrial projects, they provide both a reliable and low cost solution.

Contact Allied Modular today to learn more about how our sandwich panels can improve your next construction project.